The #Ulterra team would like to wish you and your family a very Merry Christmas! pic.twitter.com/szumfOmpX4

source https://twitter.com/UlterraBits/status/945295632935342080

The #Ulterra team would like to wish you and your family a very Merry Christmas! pic.twitter.com/szumfOmpX4

"The difference between ordinary and extraordinary is that little extra." -Jimmy Johnson #Ulterra #Motivation #Dailymotivation pic.twitter.com/1wmzH1ZO1L

The Ulterra team recently attended LAGCOE 2017 in Lafayette, Louisiana. We were honored to walk away from the event with two awards: New Technology Showcase Winner and 1st Place First Time Exhibitor. Read our latest blog post to learn more about the event. https://buff.ly/2BDZBOX pic.twitter.com/bWqdOaVw1p

#Ulterra's 8.5" CF616 drilled another Wolfcamp A lateral in Reeves Co with 1 BHA. The CF616 drilled 8,935 ft with an ROP of 130.2 ft/hr.

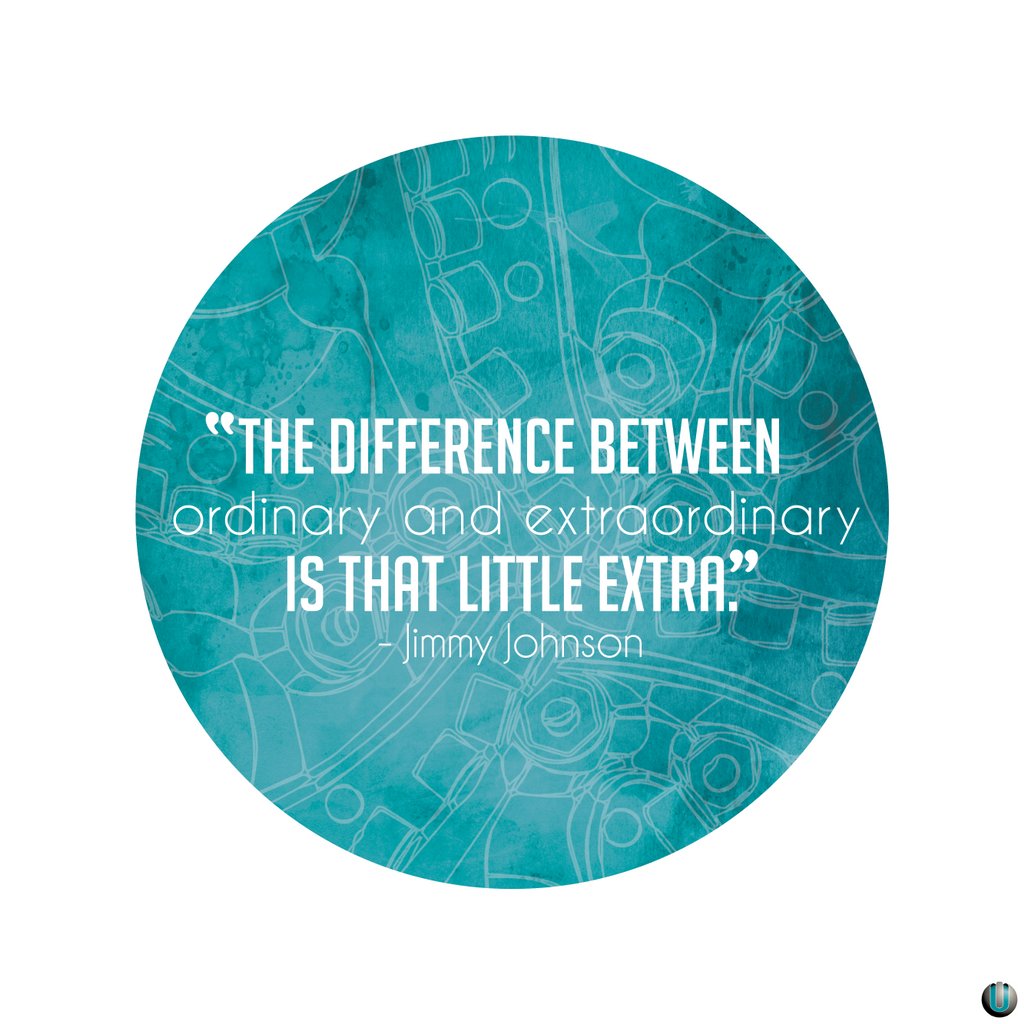

#Ulterra PDC bits partnered with @Gyrodata's GyroDrill Performance Motor set another client record in West Texas. Congratulations to all teams involved on another job well done. pic.twitter.com/Hbwq07VHfb

#Ulterra has been committed to spreading awareness about breast cancer by using our pink drill bits as a reminder to get that life-saving mammogram. Read our latest news release to learn more about our involvement and why this cause is so important to us. https://buff.ly/2BAsRWL pic.twitter.com/uElEHOFHIA

#Ulterra's 12.25" CF716 completed back to back intermediates in West Texas with one bit drilling with XTO. The first well drilled 7,766 ft with an ROP of 89 ft/hr and the second drilled 7,627 ft with an ROP of 116 ft/hr.

Drilling with Statoil, Ulterra's 8.75" CF516 set a Statoil record drilling the curve in 6.28 hrs in North Dakota.